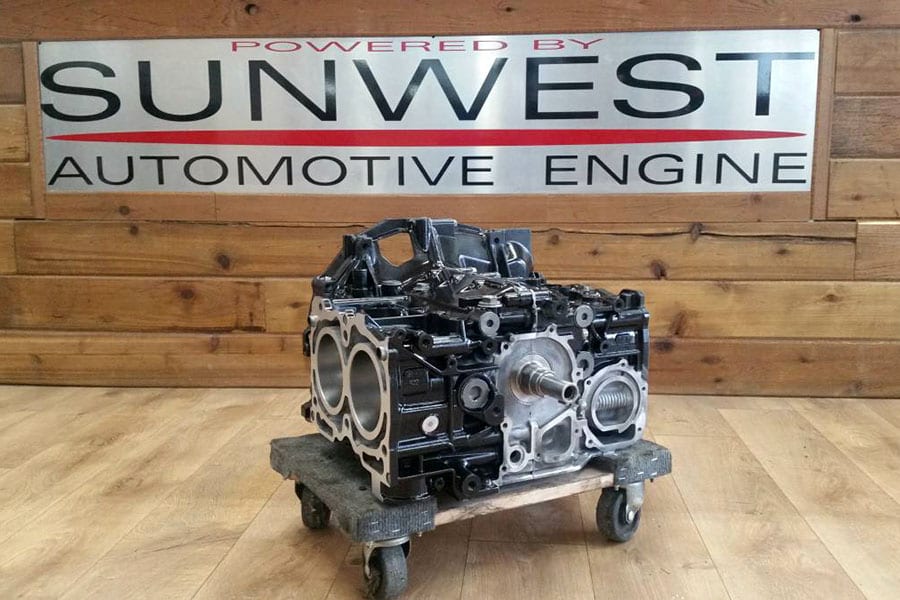

Subaru

All of our Subaru engines are remanufactured at Sunwest Automotive Engine with state-of-the-art equipment under the strictest of standards using only premium quality parts. Our engines are built to not only meet, but exceed OEM quality. We sell long blocks, short blocks, and cylinder heads and we offer a variety of options including performance packages with forged internals for people that want to get a little more out of their Subie

All engines are remanufactured at Sunwest Automotive Engine's facility in Medical Lake, WA. We ship nationwide for a reasonable rate. Our engines are sold on an exchange basis which means we need your core back. There is a core deposit required that is refundable, as long as your core that we receive back is rebuildable.

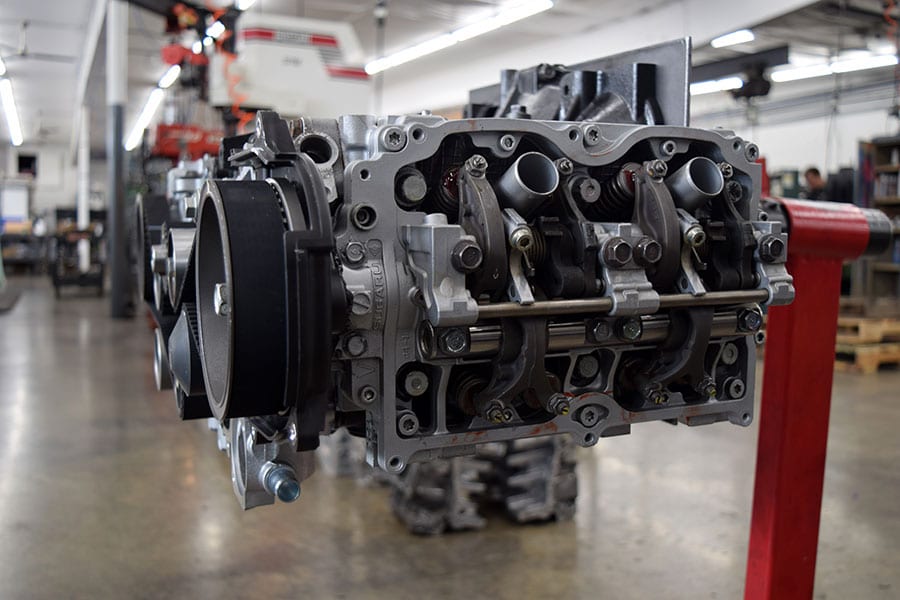

All our Subaru Short blocks include

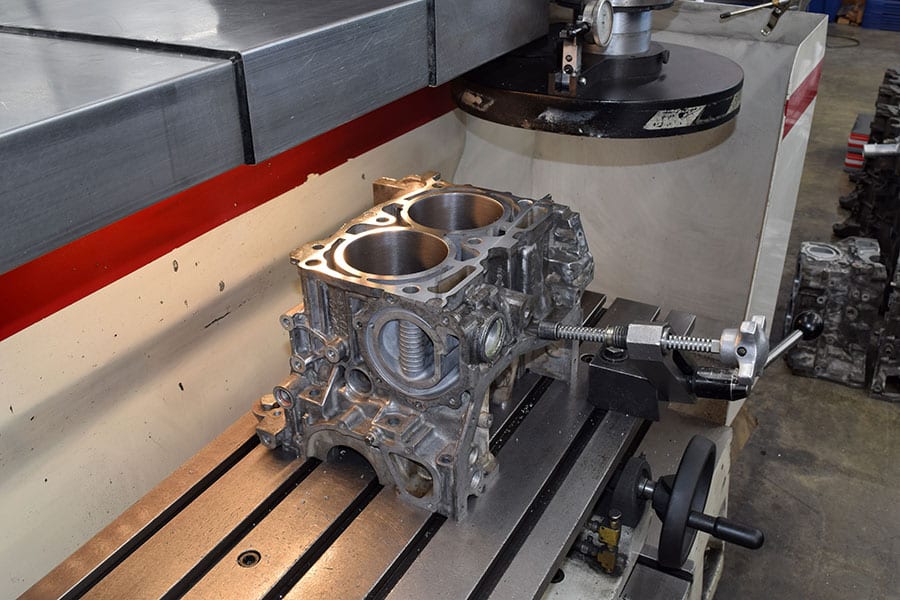

The above is a pair of Subaru case halves being honed with torque plates. This is how ALL Subaru engines should be done. Because once they are torqued down, they mimic the cylinder distortion of an assembled motor (as if the heads were bolted to it). This keeps our clearances EXACTLY where we want them.

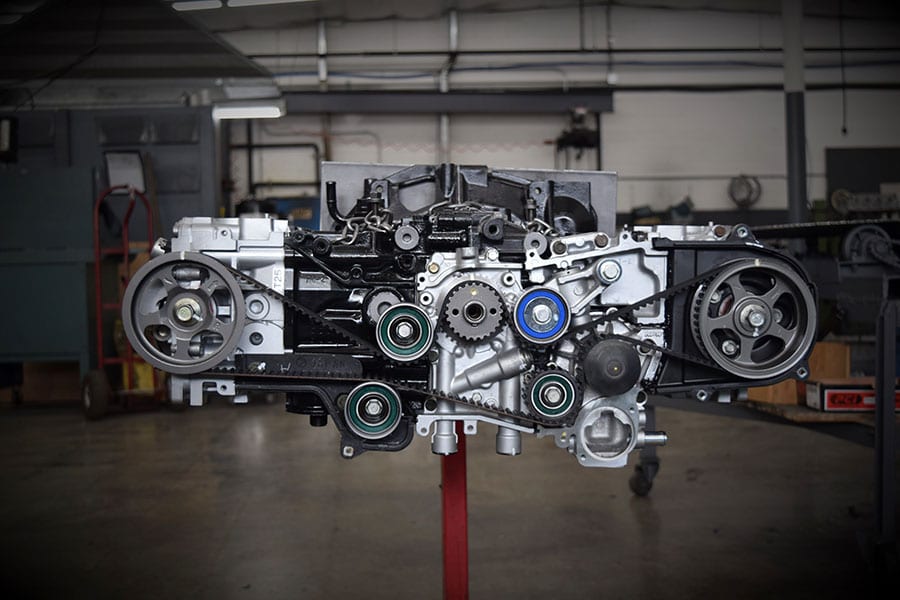

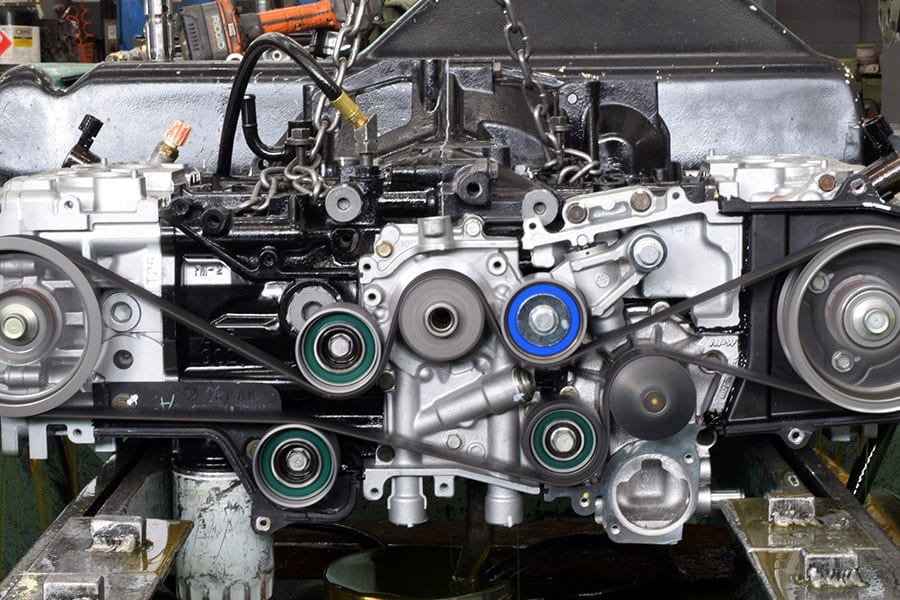

All Long Blocks are pre-ran on our SIM test machine to give an accurate reading of oil pressure, cylinder compression and engine load

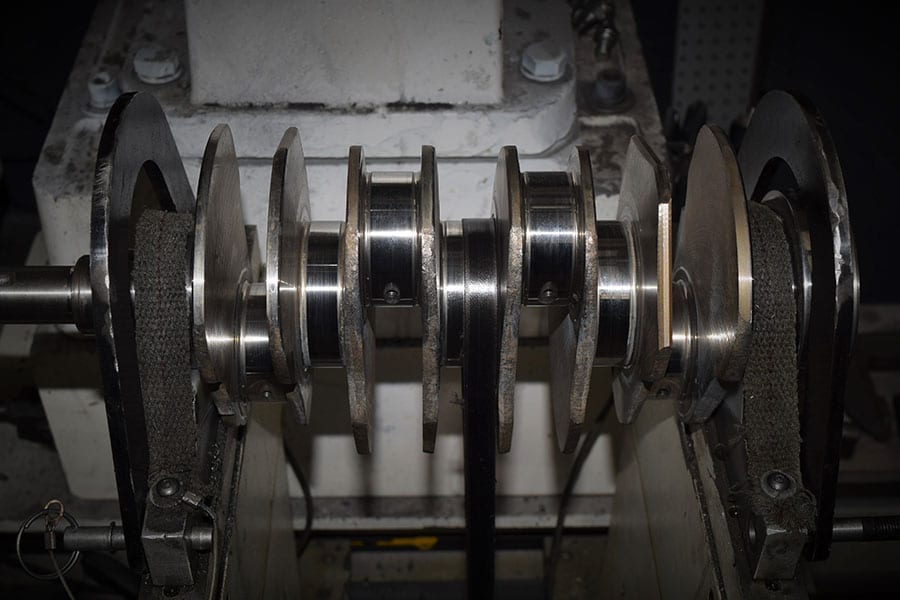

Machine Work Done: